As the coronavirus pandemic continues to sweep across the US with record breaking infection rates, some companies took it as an opportunity to increase automation technology in the manufacturing sector.

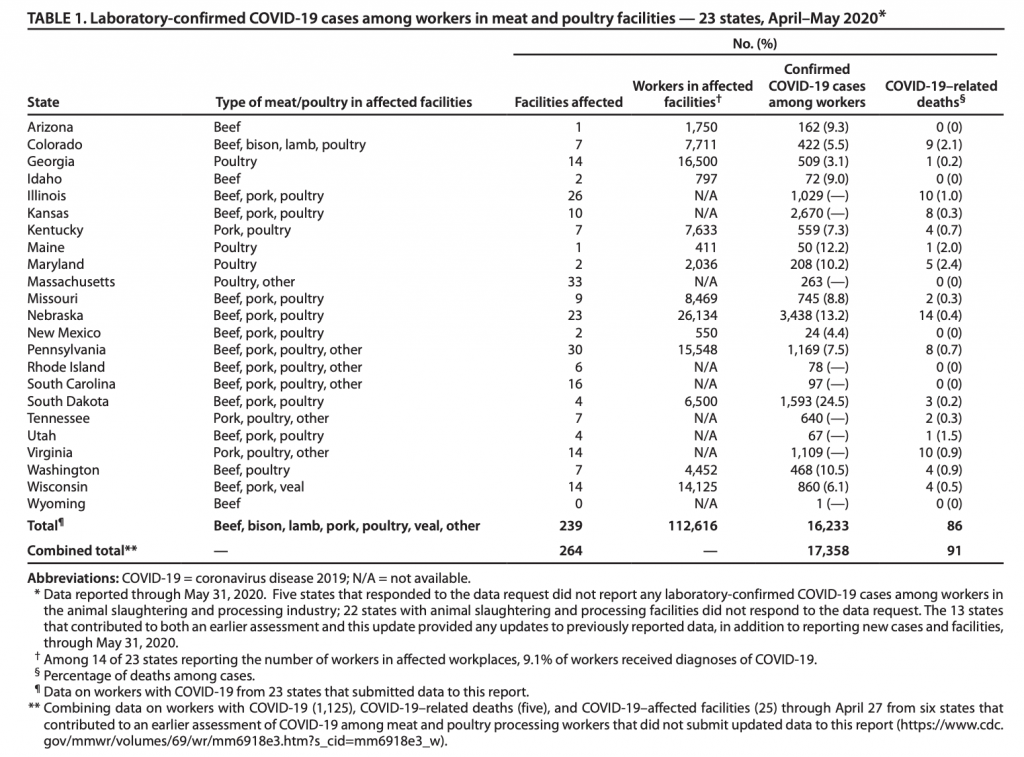

The Wall Street Journal recently reported that Tyson Foods has turned to replacing human meat cutters with robots, as a move to reduce risk of coronavirus infection among its workforce, as well as to overcome increasing labour shortages. As of May 31, over 16,000 poultry and meat processing workers have been confirmed to have COVID-19 across the US, as typical working conditions in plants require employees to be in very near proximity of each other.

Prior to the pandemic, Tyson Meats had already put nearly a half billion dollars towards automation technology; now however, the meat-processing giant plans to continue increasing its investment. Although there are various benefits for manufacturing and processing companies to move towards more automation, there are of course, job-specific shortcomings as well. Other meat-processing plants that have made the move towards automation still require a labour force, given that some of the tasks require a human to slaughter and then harvest the animal.

Information for this briefing was found via the Wall Street Journal and CNN. The author has no securities or affiliations related to this organization. Not a recommendation to buy or sell. Always do additional research and consult a professional before purchasing a security. The author holds no licenses.